In Rhino, and other modeling and CAD programs, you draw in full scale. Unlike your drafting boards you do not use a scale when setting up your drawings. When re are ready to print you select the scale for the correct output.

- When entering size information in Rhino use the full dimension

- When you print information you can set the correct scale for accurate drawings

Review Chapter 8: Modeling Aids in Lynda.com Rhino 4 training.

Turn On Osnap and Distance in Cursor - Go to File --> Document Properties, Select Modeling Aids --> Cursor ToolTips, Enable cursor tooltips, Osnap, and Distance. This will allow you to see the distances and snaps next to your cursor while you make shapes.

On/Off - The tools below can be turned on and off. Make sure you know how to turn them on or off. Check the lowest bar with information at the bottom of the Rhino screen. You will see "Snap, Ortho, Planar, and Osnap (object snap) . When you see [ Snap | Ortho | Planar | Osnap ] -- the bold Snap and Osnap are On and the Ortho and Planar are turned Off.

Grid - Set the size and units for your grids. (Think of your grids similar to drawing with an underlay of graph paper.) You can change the size of the grid at any time in your project. I start by thinking of the size of graph paper I need for my project.

- Under file select Document Properties

- Select Grid Properties

- Set the Grid Extents to be the overall size of your grid layout (just larger than your overall size of your design project)

- Set the Minor Grid lines to 1/2 your smallest tolerance, (for example if you are drawing to the nearest inch set your Minor grid line to .5" (or 1/2 inch)

- Set the Major lines every times it take to equal one foot. If you set the minor grid lines above to .5" then it would take 24 . 5 inch minor grid lines to make 1 ft major grid lines. If you set your minor grid lines to 1" then you would have 12 minor grid lines to have 1 ft. major grid lines.

This setup is very important. You will want to coordinate your Gird and your grid snap.

- If you are unsure of what to set your Grid use .5 inches for your minor grid and 24 for your major grid. This will make a grid with 1/2 inch minor line and 1 foot major lines.

- You can always change your grid later if needed.

Grid Snap - Grid snap allows your cursor to "snap" or lock to your grid above when making shape in Rhino. Using grid snaps if VERY important for accurate drawings. If you set your grid snap to 1" then your cursor will draw to 1" sizes. With a grid snap of 1" you can make a line 12" long, but not 12.5 inches long.

- Under file select Document Properties

- Select Grid Properties

- Set your Grid snap to twice your minor grid snap.

Object Snap - The object snap tool allow your cursor to easily find endpoints, intersection, center points, tangents. etc... This is very important setting to have accurate models.

- At the bottom of the Rhino screen click on the Onsap

Ortho - Make your cursor draw at 90 degree angles. This is a great tool when you want to move things in 90 degree relationship to each other or

Layers - Layers are used to organize your modeling information.

- Create a construction lines layer. Use this layer to create lines used to make objects for your models. Think of these lines like your construction lines for drafting on paper to fine center points.

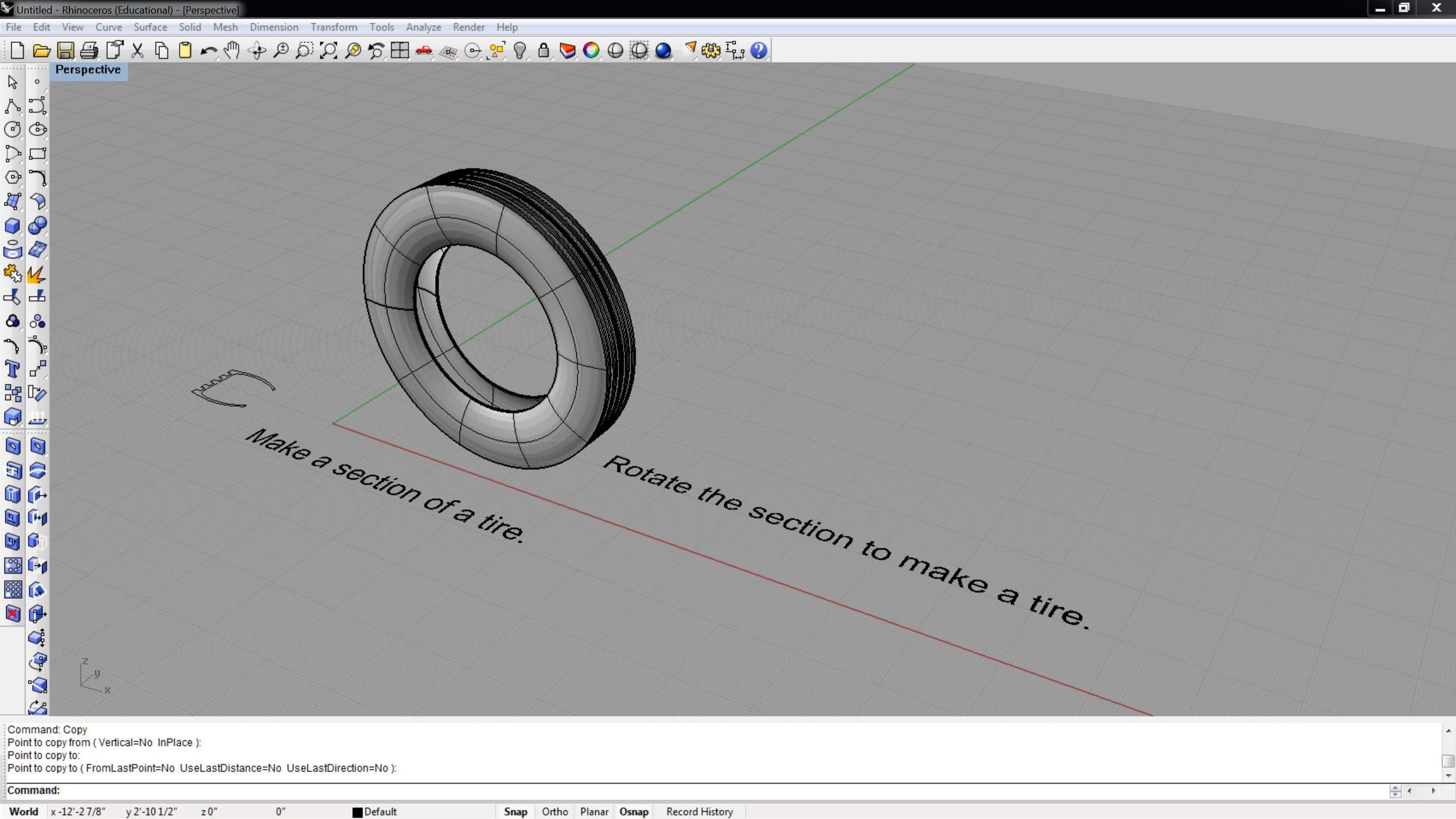

Full Size Image